Industrial Waste Management

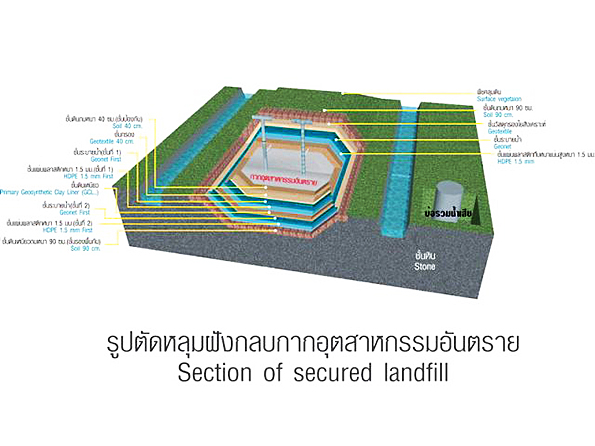

To retain a high standard and high level of environmental safety, the company has developed and designed sanitary landfill under the Pollution Control Department (PCD) standard system along with the German standard (TA Abfall) in order to reach the ultimate qualitative standard and safety. The landfill consists of a lining system (namely bottom soil), synthetic material, drainage, a filtration layer and a soil barrier (as shown in picture).

Furthermore, closed landfill systems can prevent the landfill by rain absorbing after waste has been fully buried and leveled. The system is designed according to the lining system. In particular, the process of waste water collection is aimed for draining leachate so it can be treated; and gas ventilation systems are used to release gas to environment naturally.

Secured Landfill is a place for waste after blending process this is to ensure that to highly reduce pollution to environment such as contamination of ground water or gas emission. Solid waste blending should have characteristic such as unconfined compressive strength which testing accord with ASRM D – 2166, result not less than 3.5 kg./square centimeter and density not less than 1.15 ton/cubic meter, extract fluid under standard level and pH test ranking between 9-11. After complete the process and testing, solid waste blending will move to secured landfill.

The company provides service as operate chemical and biological waste water treatment for industrial factories and capable to treat of 450 cm3 of waste water per day. Treated water can be reused in the factories which can give drastic savings in energy costs. (As shown in picture)

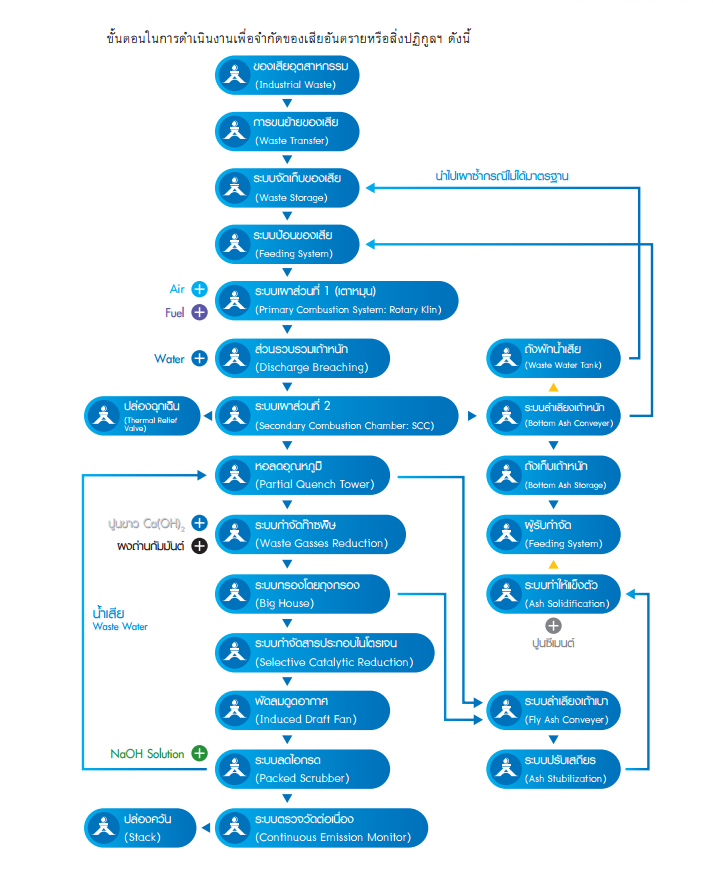

This proposes system aims to utilize resources from waste materials to provide synthetic fuel or raw materials in cement and industrial incinerators. For example, the use of fuel substitution in Thailand’s first industrial waste incinerator, constructed by the Department of Industrial Works, who granted Akkhie Prakarn Public Company Limited to operate and manage the Operation Center within a period of 20 years. This particular system can support burning of hazardous waste in a variety of forms, such as solid, sludge, liquid, solvent, oil, gas and infectious wastes of up to 48 tons per day or 15,000 tons per year.

There are 2 types of waste treatment methods:

• Solid blending, which is used to make material substitutes

• Liquid blending, which is used to make fuel substitutes

Wastes being treated must also be ‘parameter tested’, for example flash point, heating value, acid-base value, viscosity, to name but a few.

Process of Burning System

The treating of waste materials must be carefully controlled and concern to prevent impact to the environment. Thus, chemical waste analysis is carefully examined with a view to realizing essential substances and analysis methods must be authorized regarding to national and international law, which the company perceives of environmental concern and no harm to nature.

The laboratory of the ‘Better World Green Public Company Limited’ has been affirmed and admitted as operating under license by the Department of Industrial Works, no. ร-233, where locate at 140 Moo.8, Tambon Huayhang, Amphur Kaengkoy, Saraburi province, which is in “Saraburi Industrial Waste Management and Disposal Centre”, and allowing to analyse 84 types of waste.

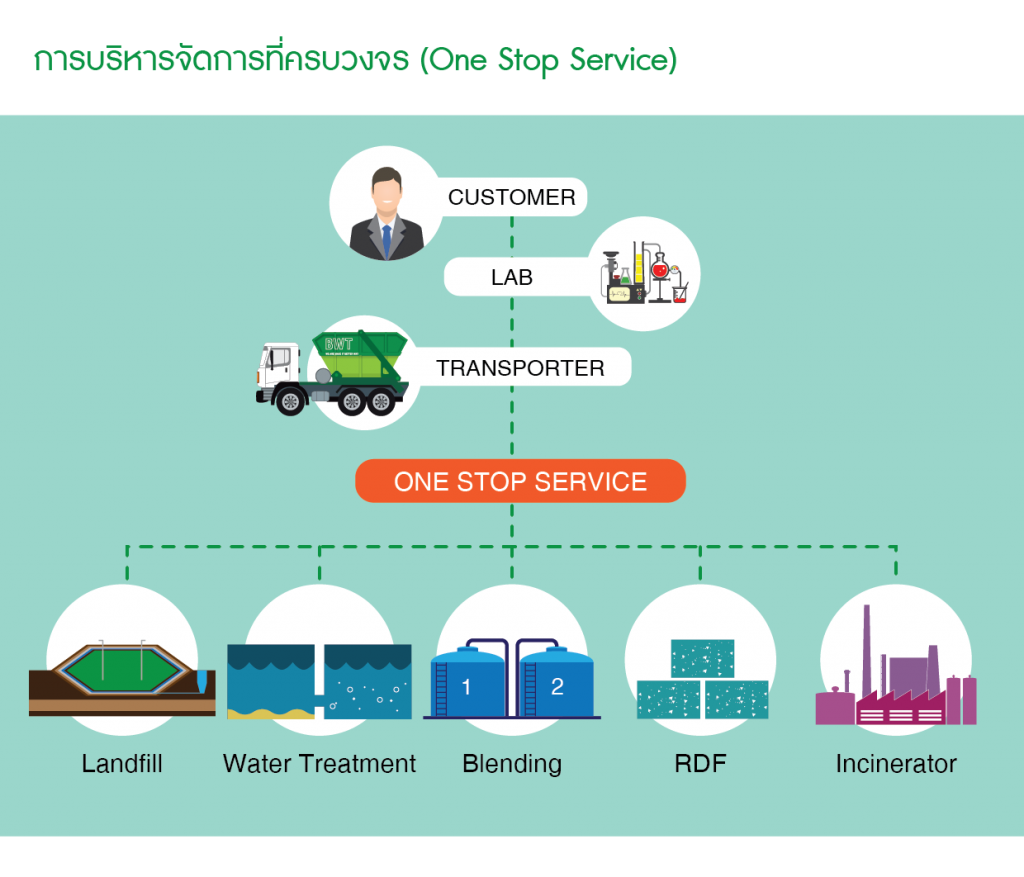

The company has operated experienced in treatment and disposal of hazardous and non-hazardous industrial wastes for more than 11 years. Along with promoting qualitative improvement to the country’s waste analysis capabilities, it provides waste management consulting services to its customers in the following areas:

• Waste management and disposal methods

• Transportation and collection system

• Waste water treatment

• Waste manifest system

• Activities for society